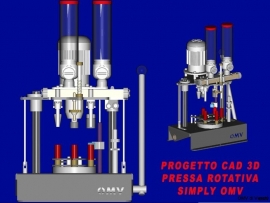

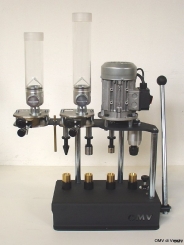

SIMPLY PRESS ROTARY, This is a machine 6 stations for loading ammunition for hunting and shooting 12-16-20-28 and this’ can do this by replacing the’ proper disc rotation and its utensils closing cartridge. The machine ‘very easy to use, fits our dosing precision with vibration mechanism. (New mechanism patented by us with different beats settling for a dose even more ‘precise). The dosage of powder and lead occurs through convenient knobs, for micrometric adjustment, to arrive at the desired dose in a fast and precise. The tanks are made of tempered glass tubes, not to pass on to the dust electrostatic charges. The crimper steel is adjustable in height and is rotating to resume the folds of crimping shells already’ fired.

The machine can ‘be used in semi-automatic, or excluding dosing powder and lead in mode’ manual. I mean ‘for example we can fill cartridges with other feeders outside, and use the machine only for crimping and closing . This also thanks to the rotating disk that can ‘be rotated back and forth manually. (Patented mechanism) The Press and ‘available in two versions: BASIC MODEL (Fit for size 12-16-20-28), or MODEL WITH crimp RIBASSATORE (Essential for caliber 410). All machines can be converted with the basic model system ribassatura, even in later times to ‘purchase. * The machine is supplied complete loading a gauge choice, the others are optional.

Latest version of SIMPLY, E ‘was beefed up the engine, with toothed belt drive carrying the’ hemming at 900 rpm thus increasing the engine power of 40%, this way you have a little effort on the lever, and no overheating of ‘crankshaft. This results in greatly improved the closing of the cartridge. (Soon insert new video).

KIT AIR SISTEM PER PRESSA SIMPLY

AIR SYSTEM This system can be applied to all the presses Simply, allows the descent and ascent of the machine automatically, and hands free you can then prepare for the next loading. Requires a small air compressor (not included) of about 50/100 liters, the working pressure and ‘only 4.5 bar. How can ‘see from the photos we have also included a count cartridges. The kit is easy to install by yourself, (see video).

Simply press model 6 stations with crimp station, suitable for small calibers, in the picture you can see equipped for the caliber 410.

.

.

.

.

no images were found

no images were found

no images were found

no images were found

.

.

.

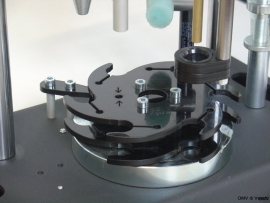

Kit optional for gauce 12-16-20-24-28-32-410 ( rotating disk – Crimper steel 6 star – crimper for closure – guide bushing for crimper )

.

Description of the processing stages (SIMPLY)

Station 1: Mounting shell and inserting new dose powder.

Station 2: Inserting wad manually

Station 3: Inserting dose lead.

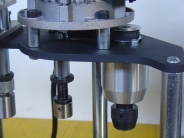

Station 4: crimping.

Station 5: Close to size with hemming and ejection of the cartridge case.

Station 6: This station is used for the ‘inclusion of shells recovery (already’ recalibrated and triggered in part), and by an adjustable cone allows to widen the mouth of the cartridge.

Specifications:

– Motor Italian motor with toothed belt drive 900 rpm

– Supply voltage 220 volts

– Machine structure in stainless

– Slides of ground steel and chrome

– Movements on bronze self-lubricating

– Dosing micrometric precision vibrating (accuracy 0.03 g.)

– Dosatua powder 0.70 g. to 2.50 gr.

– Tube tank glass and plexiglass dust for lead

– Dosing lead to 11gr. to 52gr. (Tested with lead 3 to 12)

– Attack crimper M6 (on demand reduction for 10×1)

– Overall weight 28 kg.

– Machine CE certified

– 2 years warranty